Manual cleaning versus machine reprocessing of laboratory glassware and utensils

Experiments and analyses in laboratories require a steady supply of clean laboratory glassware in sufficient quantities. Excellent and reliable results can only be achieved if laboratory glassware and utensils are clean and residue-free from the outset. In other words, items should be free from any impurities and the process chemicals previously used. Producing this level of consistent quality is rare when using manual cleaning methods, which leave laboratories open to the risk of compromising the standards required for analytical work.

Even today, the manual cleaning of laboratory glassware is still commonplace. The reasons for this approach are usually pecuniary in nature – manual cleaning is cheaper than procuring and maintaining a laboratory glasswasher, or at least that is the general perception. Looking at the pros and cons more closely, this supposition turns out to be a fallacy.

Manual cleaning as a source of errors

Cleaning at the sink is not only messy and cumbersome but a great deal of time and effort is also required to achieve the desired results. The time spent by laboratory staff can be put to much better use when reprocessing is automated. Similarly, consistently high standards of cleaning are difficult to achieve in a manual process. Manual cleaning results always depend on the person doing the work. Experience, the procedure and the time available all impact the outcome.

Manual cleaning involves a particularly high risk of damaging expensive items of laboratory glassware: Mishaps when handling materials, cleaning utensils and chemicals significantly reduce the service life of glassware. At the same time, such a constellation poses a health risk to laboratory staff as employees breathe in aerosols, come into direct contact with chemicals or injure themselves on broken glass.

Machine reprocessing: an investment that pays off

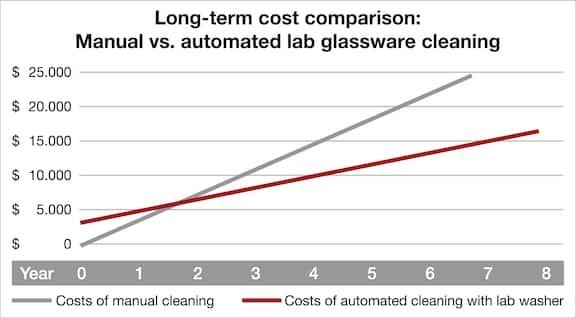

Given the initial outlay for a commercial laboratory glasswasher, users often question whether such a major investment will pay off. They often, though, fail to see the long-term savings which come with machine reprocessing.

First and foremost are time savings: Staff members can devote their valuable time to other, more productive tasks, making their work more efficient. At the same time, they are relieved of laborious and unhealthy chores, resulting in reduced sick leave and increased levels of satisfaction and motivation among lab staff. Furthermore, speed is a clear advantage of cleaning laboratory goods in a lab washer. While manual cleaning and rinsing takes approx. 1 minute per glass, 60 lab glassware items can be reprocessed automatically in only 36 minutes in a machine, which corresponds to a time saving of about 59%.

Add to this the responsible use of valuable resources: The consumption of energy, water and process chemicals is precisely geared to individual processes and achieves top-class results without wastage. Water consumption in an automatic process is up to 63% lower compared to the consumption in a manual process. This not only helps laboratory finances, it also considerably reduces the burden on the environment. And, last but not least, machine reprocessing is far gentler than washing by hand. The risk of etching, scratches or glass breakage is reduced to a minimum and the life cycle of reprocessed goods is extended.

Everything speaks in favour of laboratory glasswashers

The higher investment cost of procuring and equipping a laboratory glasswasher pays off in the long run. First-class consistent results alone are reason enough to buy a laboratory glasswasher. But lower labour costs, the reduced consumption of electricity, water and process chemicals and the longer life expectancy of laboratory glassware will sooner or later tip the balance. The amortization period depends of course on individual cost structures and how many program cycles are run per day, but calculations based on average figures show that the investment in a laboratory glasswasher can pay off in less than 2 years.

And, last but not least, a laboratory glasswasher makes reprocessing in a laboratory much safer, less prone to mistakes and hence more reliable. In all, this makes work in labs far simpler.

To make the transition from manual cleaning to machine reprocessing as smooth as possible, Miele Service and authorized Miele service agents are close at hand throughout the life of a laboratory glasswasher. From installation and commissioning through to selecting the correct programs and chemicals and providing assistance with issues, maintenance and repairs.